Waterjet cutting

The optimal material use is guaranteed by CAD cutting plans.

Range of treatment

Steel: 1mm up to 140mm thickness, size: 3000x1500mm

Stainless steel: 1mm up to 140mm thickness, size: 3000x1500mm

Aluminum: 1mm up to 200mm thickness, size: 3000x1500mm

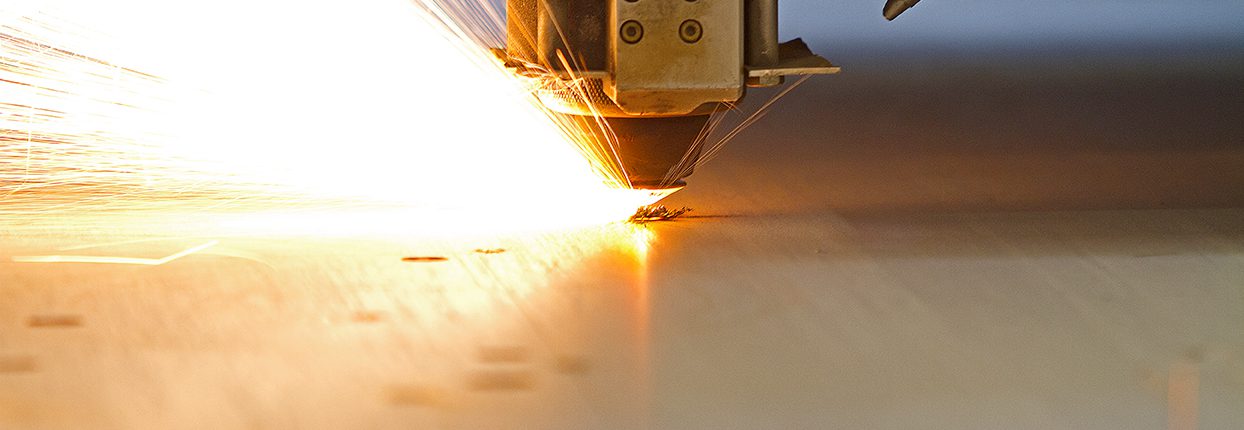

Waterjet-Cutting in action

This is how our waterjet machine works.