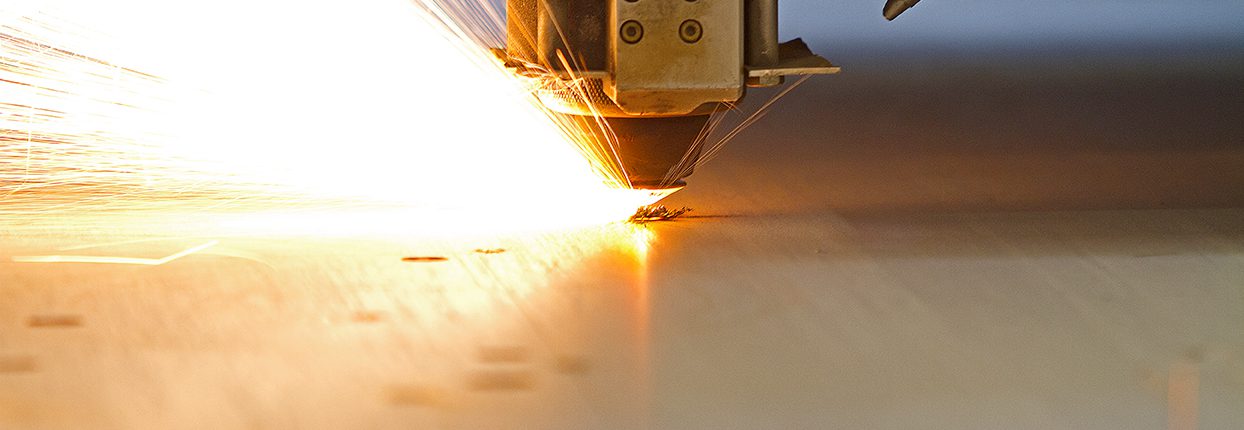

Flame Cutting / Oxygen Flame Cutting

Oxy-fuel cutting is one of the most important production processes in the metal industry.

The heating flame heats the workpiece to be cut to the ignition temperature of the material. A jet of at least 99.5% pure oxygen is then blown onto the heated area.

Burning begins and the oxygen jet works its way through to the underside of the material. The burner is moved and a narrow parting line is created. All low-alloy steels can be cut using this process.

Machine flame cutting guarantees fast, safe grooving, high cutting speed and enables components to be manufactured with little rework.

Production of oxy-fuel cutting:

We cut from 40 to 150mm thickness.

Advantages of oxy-fuel cutting:

Good cutting quality, smooth vertical cutting surface

Metallurgical perfect surfaces (oxidized)

Highlight

Bores up to a maximum of 32 mm can be produced in one operation.

Flame Cutting / Oxygen Flame Cutting

This is how our flame machine works.