Plasma cutting

Plasma cutting was originally developed for thermal cutting of materials that are not suitable for oxy-fuel cutting, such as high-alloy steels or aluminum. Today the process is also used for economical cutting of low-alloy steels. The cutting area for plasma technology depends on the material and is approx. 0.8 to 160 mm thick. Up to a thickness of around 50 mm, plasma cutting is faster than oxy-fuel cutting.

Today’s plasma fine-jet technology enables high-quality cuts with extensive beard-free, low surface roughness, small angular deviation and high repeat accuracy.

Production of plasma cutting:

We cut from 20mm to 40mm thickness.

Advantages of plasma cutting:

Good to very good cut quality

Straight cut surfaces

Metallurgically perfect surfaces (oxidized) or nitrided

Medium heat input

Little hardening at the cut edge

High cutting speed

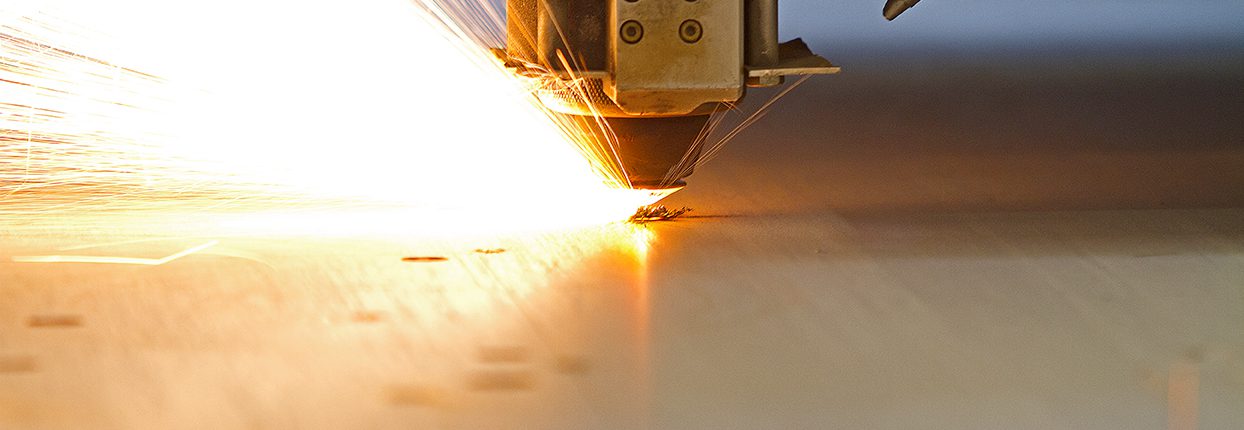

Plasma cutting in action

This is how our plasma machine works.