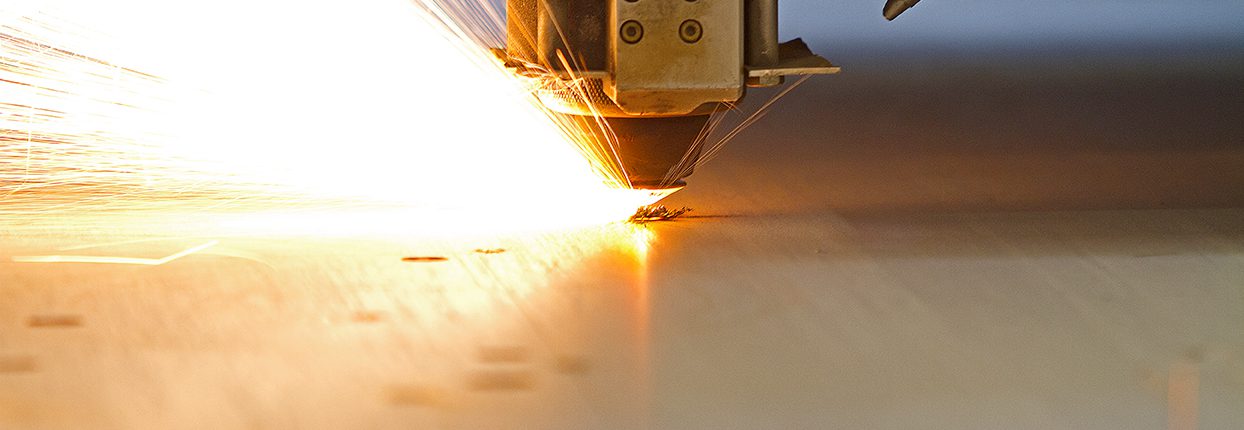

New machine - additional scope of service!

We have added to our existing range of machines!

Manufactoring

- If not listed separately, all parts are offered without deburred edges, without mechanical processing and without straightening

- Glass, Plexiglas, ceramics and tiles: for technical reasons there is no guarantee for a scratch free surface, there may be unwanted edges as a result of the cutting process.

- Drawing files (see below)

- Tolerances according ton ISO 9013 – see below charts

- Tolerance category I: Laser/Waterjet

- Tolerance category II: Oxy-fuel/Plasma

- Always medium quality of cut and most cost efficiency method of cutting

- Caution! With water jet cutting, the smallest tolerance is +/- 0.2mm!

- Tolerance classes do NOT apply to plastics, in particular to fibers and laminates, such as GFK, CFK, Kevlar, CFC and AFK. The cut can become more oblique here or layers can come loose!

- TOLERANCES for evenness and thickness tolerance (structural steel) = DIN EN 10029

- TOLERANCES for evenness (stainless steel) = DIN EN 9444

- Long narrow parts can get crooked!

- Blanks that taper to a point are rounded off, a radius is created, the size of the radius is determined by the material thickness.

- With inner 90 ° corners a radius is created, the size of the radius is determined by the material thickness.

Provision of drawing files

CAD formats and drawing specifications suitable fpr adoption:

- DXF 2D

- DWG 2D

- Drawing scale 1:1

Layers and colors:

- Outside and inside contour on a seperate layer (color green)

- Marking on a separate layer (color yellow)

- Smallest diameter = 0,5x material thickness (laser)

For dimensions with tolerance requirements, the AVERAGE DIMENSION must always be drawn, not the nominal dimension!

Tolerances deviating from ISO 9013 must always be discussed with our work preparation department and require our approval!

If CAD files are provided, we will manufacture according to your drawing data on a “1: 1” scale!

We do not accept any liability for any form or dimension deviations due to a lack of compliance with our specifications.

Formats not suitable for adoption (program costs according to effort):

- PDF / TIF / JPG / EPS

These and similar formats cannot be used for production and have to be programmed or digitized depending on the effort involved – we are happy to offer this to you separately!

If required

- Work certificate 3.1 EUR 12,00 per piece

Since October 10, 2018 we are authorized according to AD 2000 rules and similar rules and for the construction industry to re-stamp.

- Certificate for re-stamp EUR 12,00 per piece

- Certificate for re-stamp

of individual cut EUR 3,50 per piece

Order processing

Terms of payment

Individuals: advance payment

New customer: 20 day net after date of invoice, subject to a satisfactory checking by our credit insurance

Orders

Minimum size of order: EUR 30,00 net

Transportation

Forwarder: from app. 31kg up to 250kg (1 Europallet)

1 EU pallet up to 250kg send to postal code 40-42, 44-48 = EUR 85,50 per piece

1 EU pallet up to 250kg send to all other postal codes = EUR 108,20 per piece

incl. insurance

More favourable rates may be available but only in case of extended delivery periods.

Special formats: after prior consultation

Transportation

per DPD

up to 5kg = EUR 7,00

up to 10kg = EUR 12,00

up to 15kg = EUR 15,00

up to 20kg = EUR 20,00

up to 25kg = EUR 22,00

up to 30kg = EUR 25,00

Validity of quotes

Our customer portal always gives you the most up-to-date price of the day.